KEY SPECIFICATIONS

- Increased kW Capacity

- Advanced mixing gas operation

- Digital power display is solid state

- Multiple mode circuits with automatic audio/visual digital display

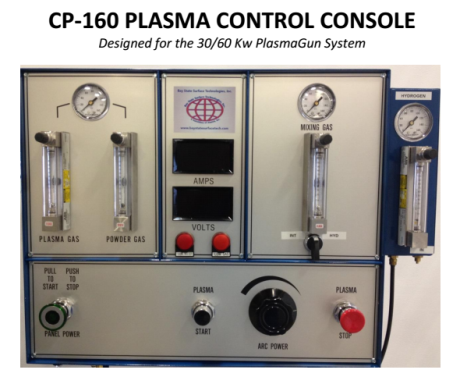

The Brand new PlasmaGun Control Console CP-620 has a time tested reputation of having incredibly simplified operation, compact styling, and a very small amount of maintenance. It has a plethora of features that are necessary for today’s plasma spraying operations, that make tomorrow’s creation and advanced technology keep moving forward. The CP-620 allows for increased gas volume and multiple gas mixing capabilities, so a large variety of high energy, and high velocity specs can be achieved. We have added several new features to the CP-620 without taking away any of the close parameter, compact aspects, that we love so much about our plasma guns, that allow us to get close to the substrate necessary for plasma spraying. We have included controls of some of the more primitive auxiliary equipments such as water control circuits as well as supply cooling. To top that all off, all required utility functioning is operated and monitored a the work station.

In heightened cases, visual and audio indicators are provided.

Another great feature of this state of the art console we added is a module switch that allows for a single selected utility circuit during operations. This feature provides very simple trouble shooting without having to lose productivity on the operations of other utilities. The aforementioned specs allow for constant monitoring of the spray gun operations without losing productivity and makes troubleshooting much more compliant. The PlasmaGun control console intertwines state of the art features to help monitor and control plasma gases. The system not only monitors flow and pressure of the forming plasma gases or gas mixtures, but also provides the availability to operate with a vast array of gases. The use of charts and percentage meters allows for a single meter to be used to set all gas glows in Metric units or English. Also included is a protective circuit that alleviates flowmeter breakage caused by high-pressure gas surges.

Alos included in the monitoring and electrical control circuits is a brand new, highly accurate digital readout for both current and voltage. At first glance, current and voltage can be controlled or observed at the exact point of operation. The control of the water cooling system is provided by the circuitry control console is essential for efficient operation and protection of the plasma spray gun. Circuitry is provided to automatically shutdown the CP-620’s operations should the water system falter in any way. This is attained by interconnecting a a booster pump, heat exchanger, or flow switch kit. This monitoring system provides both audio and visual indicators, and is down without needing any water flow through the PlasmaGun’s console. The CP-620 PlasmaGun control console makes all operations simplified for the plasma spraying process. The simplified troubleshooting parameters enable the spray technician to easily determine the source of operational error. It makes the plasma spraying operation a simplistic and efficient one.

Specifications

| Electrical Inputs to Control Circuits: | 110-VAC-60 HZ Supplied from Power Supply | |

| Auxiliary Functions: | Automatically controls and monitors: 1) Water cooling systems 2) D.C. Power Supply |

|

| Safety Interlock: | Automatic shutdown at system overload | |

| Gas: | Flow | 225 SCFH Argon @ 50 PSI 290 SCFH Argon @ 100 PSI |

| Inputs: | 1) primary, mixing gas #1, mixing gas # 2 | |

| Outputs: | 2) to PlasmaGun, to Powder Feeder | |

| Maximum output capacities: (Based on a specific gravity of 1.0) |

Primary -350 SCFH @ 100 PSI = 2.75 @ 60 KPA Powder -64 SCFH @ 100 PSI = .5 SLS @ 60 KPA Mixing Gas -#1-8 SCFH @ 50 PSI =.06 SLS @ 345 KPA Mixing Gas #2-112 SCFH @ 100 PSI =.9 SLS @ 690 KPA |

|

| Control: | Independent metering of plasma, mixing and both mixing gases | |

| Safety Interlock: | Automatic shutdown at low gas pressure | |

| Water: | Input: | Tap water @ 3 to 5 GPM @ 80 to100 PSI |

| Control: | Interconnection provided with water flow switch/booster pump or heat exchanger | |

| Safety Interlock: | Automatic shutdown at low water flow | |

| Powder Feed Control: | Controls powder feed carrier gas | |

| Dimensions: 22″ wide (560 mm) x 7″ deep (178 mm) x 18″ high (457 mm)

Weight: 48 pounds (22 kg) |

||

National Alloy Solutions employs the cutting edge plasma spray technology to ensure that clients obtain exceptional results from their plasma coated accessories and surfaces. We Masking Products | thermal spray technologies | hvofknow the dynamism of the dynamic environment that your items are often subjected to. We have carefully sorted and selected techniques that withstand harsh environments such as coats plasma spray, which allows your items to undergo repair, modification, or coating without changing their initial design or workings. Plasma spray is used in HVOF environments comfortably because National Alloy Solutions has invested in research to use the plasma spray variant that suits each customer’s specific requirement.

If you are looking for a unique thermal spray coating that enables your surface to survive extremities in temperature and intense heat conditions, give us a call. National Alloy Solution offers clients a complete range of thermal spray, hvof, plasma powders, and plasma spraying technology options that is executed with state of the art equipment. We invest in research because we know that clients deserve the best.

Fill out our contact form on the right of this page, or>>>>>Contact us Here<<<<<