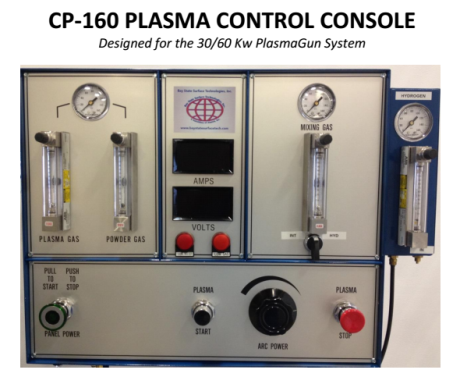

Some Key Feature of the CP-120 Plasma Gun Control Console

- It has a very solid design

- Availability for mixing gas

- Components are all self aligning

- Digital Power Display for Solid State

- Has auto audio and visual troubleshooting

- Come with an optional module for hydrogen mixing gas

This plasma gun control console is very cost effective and can produce extremely high quality plasma spray coatings that you would normally see on systems that much more expensive than this model. It allows for close to workplace maneuverability as well as supporting time tested ideals such as requiring very minimal maintenance, close quarter styling, and very simplified operations. All operations that are required to make the model perform daily duties are monitored and controlled right at the work site. When critical areas arise, visual and audio indications are given right on the solid state.

Although the Plasma Gun Consol CP-120 can be used with a vast variety of power supplies, it is best used with the NAS PS-2010 30/60 Kw power source, or as a integral piece to the NAS portable palletized system, due to their versatile and very dependable aspects. When using NAS plasma guns, a full array of coatings can be adhered to a substrate. These include Metals, Carbides, and Ceramics.

The CP-120 plasma gun console has state of the art features that monitor plasma gases, and controls them. This system not only monitors the pressure of all plasma forming gases and mixtures, but it also facilitates for the mixing of multiple different gases. Due to this unprecedented feature a single meter can facilitate to set all gases and flows into english or metric units and uses percentage meters and charts to accomplish this.

A digital readout for both current and voltage, is shown on the monitoring and electrical control and monitoring circuits. With little effort current and voltage can be controlled and monitored at the exact point of operations. The control console can control the water cooling system with is vitally important to the protection and efficiency of the plasma gun. Circuitry, in the control console, can provide automatic shutdown of the plasma gun, should the water system fail, if interconnecting with a flow switch kit, closed loop heat exchanger or booster pump. Visual and audio indicators are also provided by the monitoring system. This is all facilitated for without the need for water flowing through the unit itself. The CP-120 console was created to provide simplified operations for every facet of the plasma spray process. By way of gas, water, and electrical control and monitoring, all important framework of the spraying process can be maximized. It makes the whole plasma spraying process a simplistic and easy to use operation.

Specifications

| Electrical Inputs to Control Circuits: | 110-VAC-60 HZ Supplied from Power Supply | |

| Auxiliary Functions: | Automatically controls and monitors:

|

|

| Safety Interlock: | Automatic shutdown at system overload | |

| Gas | Flow | 190 SCFH Argon @ 50 PSI |

| Inputs: Outputs: |

1) Primary, mixing gas 2) to PlasmaGun, to Powder Feeder |

|

| Maximum output capacities: (Based on a specific gravity of 1.0) |

Primary – 190 SCFH @ 50 PSI = 1.5 SLS @ 345 KPA Powder – 41 SCFH @ 50 PSI = .3 SLS @ 345 KPA Mixing Gas – 12 SCFH @ 50 PSI = .09 SLS @ 345 KPA |

|

| Control: Safety Interlock: |

Independent metering of plasma and mixing gas Automatic shutdown at low gas pressure |

|

| Water: | Input: Control: |

4 to 6 GPM @ 80 to 100 PSI Interconnection provided with water flow switch/booster pump or heat exchanger |

| Safety Interlock: | Automatic shutdown at low water flow | |

| Powder Feed Control: | Controls powder feed carrier gas | |

| Dimensions: | 22″ wide (560 mm) x 7″ deep (178 mm) x 18″ high (457 mm) | |

| Weight: | 48 pounds (22 kg) | |

To get a Free quote for the PG-Series 120 Control Console contact National Alloy

Solutions by>>>>>Contact us Here<<<<< or give us a call at 713-591-4994